Foreword: At Antique Lamp Supply we take pride in quality lamp parts and great service. We have been in the lamp business for a while and have done the homework. Fabric shades, like any product line, have distinct characteristics. This article helps highlight those characteristics and points out elements of a well made fabric shade and how to gage quality. In short, these elements include:

- Rust preventing coating on frame

- Well seamed trimming on top ring and bottom ring

- Rib hiding techniques like color coating, vertical piping, and using no hug

- Tight knit weave fabric and complementing lining

- High craftsmanship ensuring a long lasting shade

This article should be considered in conjunction with "3 Simple steps for selecting the correct shape and size fabric shade for your lamp" when shopping for that right shade.

When finding a fabric shade, there is a lot to think about: size, shape, color, materials, and quality. Size and shapes are discussed in another "How To" article (click here). In this article we want to focus on quality and characteristics of a well made shade while discussing some terminology of fabric shades.

Frame Work of a Fabric Shade

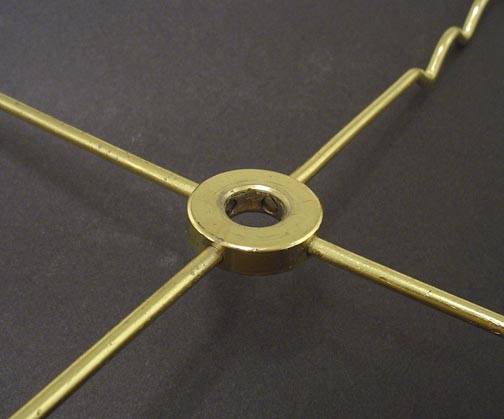

While fabric lamp shades come in a variety of sizes, shapes, colors, and materials, there are characteristics that all fabric shades have in common. All fabric shades have a fitter; a tripod spider, top ring, ribs, and a bottom ring. The fitters are mostly standard. You can find more information on shade fitters here. The tripod spider connects the fitter to the top ring and may have bends for an IES Reflector shade. The top ring is at the top of the shade. The ribs connect the top ring to the bottom ring and provide the structure to the shade. The bottom ring is at the bottom of the shade.

The frame of a fabric shade should provide structure for strength and shape but with minimal visibility. There are several techniques used to conceal the frame. The first technique is to color the frame. Most frames are made of steel and finished where the spider and fitter are located and visible. Common finishes on the fitter include brass, nickel, antique brass, and flat black. The frame inside the shade should also be finished with a color complementing the outer color. Common in light colored shades would be white or a light cream color. The finish also helps prevent the shade from rusting. Some shades may rust from exposure to the elements and the rust could bleed through the fabric and damage the structural integrity. A colored finish on the frame will protect the frame from rust and help conceal it from sight when the shade is lit or not.

Another technique used to conceal a frame is called vertical piping. Vertical piping is a strand of fabric stretching from the top ring to the bottom ring and is usually cut from the same fabric. Most high quality shades will use vertical piping. to conceal the frame and add a structured look to the overall appearance of the shade. In addition to concealing the ribs, the vertical piping is a good way to conceal the vertical seam of the shade.

| Common Fabric Shades | Antique Lamp Supply Fabric Shades |

|

|

| This shade does not have vertical piping and the ribs show through when the shade is lit. | The vertical piping on our shades conceal the ribs when the shade is lit. |

Some shapes are not intended to have any piping on the exterior. Drum shades and cylinder shades have a distinct look where vertical piping would not be appropriate. In this case the ribs bend inward; away from the external fabric to prevent distinct shadowing on the shade when it is lit. This technique is known as "no hug" because the ribs do not hug the external wall. Where a shade does not have vertical piping, finishing the frame with a similar color and using the no hug techniques will help conceal the frame.

Outer Materials of a Fabric Shade

The term fabric shade can indicate a wide variety of different shades. Typically fabric shades include all shades with the frame discussed earlier; where the ribs are covered by a material to diffuse the light from a bulb. Fabric shades can include the use of many different materials including: silk, burlap, mica, or even leather. There are two important things to consider in the materials, one is the finish and the other would be the fit.

Many fabrics can look similar, especially from a distance or to the untrained eye. There are several things to look for when examining the fabric shade materials.

First is the weave. Finer shades have a smaller, tighter knit weave in the fabric. There shouldn't be any holes, kinks, or imperfections in the weave. Even in a burlap shade, there can be differences in the weave. The weave can have a drastic effect on the print of a fabric shade. Loose weaves will cause the print to look fuzzy and out of focus. A quality fabric shade should have a nice tight weave with consistent color and finish throughout.

| Common Fabric Shades | Antique Lamp Supply Fabric Shades |

|

|

| Loose weave on burlap can create wholes in the shade. | Tight weave looks good and is consistent throughout shade |

|

|

| Loose weave can affect appearance of printed shade. | Print on fine weave and shades in color create a drastic effect. |

Second is the seams. The seams, like a tailored suit, are very important. The seams on a fabric shade should be neat, straight, and well tailored. Vertical piping. (mentioned earlier) can conceal a seam. The seam should not appear to be stretched or stressed by the frame. When selecting a quality shade, do not use the phrase "It can be turned to the back" when referring to the seam. A good quality shade will have a nice tailored seam and will not be a distraction to anyone.

Third is the lining. While not all shades require a lining (like a mica shade), the lining on a fabric shade should be as nice as the exterior material. The fit should be exact on the frame with no sagging and the seam should line up with the seams on the outside materials. A nice lining may be the same color as the outside material or a complementing color to the shade. The lining on a shade can have a drastic effect on the overall look of the shade especially when the shade is lit.

| Common Fabric Shades | Antique Lamp Supply Fabric Shades |

| This unlined shade will not diffuse the light and some high temperature bulbs may cause damage to the exterior materials. | Lining provides a finished, tailored look and protects this faux leather exterior. |

Fourth is the trimming. Trimming is a piece of material that covers the top and bottom ring. The trimming may be constructed of the same material as the shade or a complementing material. The trimming should be well sewn at the top and bottom. There shouldn't be any waves in the trimming. All trimmings have a seam where they meet on the shade. The seam of the trimming should be well tailored and almost unnoticeable. There shouldn't be any bulky over lapping of the materials at the seams and it should not hang off the frame in any way.

| Common Fabric Shades | Antique Lamp Supply Fabric Shades |

|

|

| This shade has no vertical piping so the seam is exposed. The trim seam is sloppy and should not be so noticeable. | The vertical piping on this shade conceals the fabric seam. The trimming is well tailored and fits snug to the frame. |

Packing and Shipping

All fabric shades should be packed and shipped with care. Each shade should be wrapped with a dust cover (usually a clear plastic wrap) to keep the shade clean until it is ready for use. Shipping a fabric shade can be challenging. The slightest compression of a shade may be initially unnoticed, but can have a drastic change in appearance on the shade when it is lit. Always carefully pack a fabric shade for shipping or for storing and we suggest using a dowel to hold the shade in place and help prevent compression of the shade.

These suggestions are just a few thing to keep in mind when purchasing a fabric shade. While the shape, color, and style may be a personal preference, you should always consider the quality of the fabric, construction, and workmanship that goes into the shade.